Utility Boring

Minnesota Directional Boring - Utility Boring Contractors

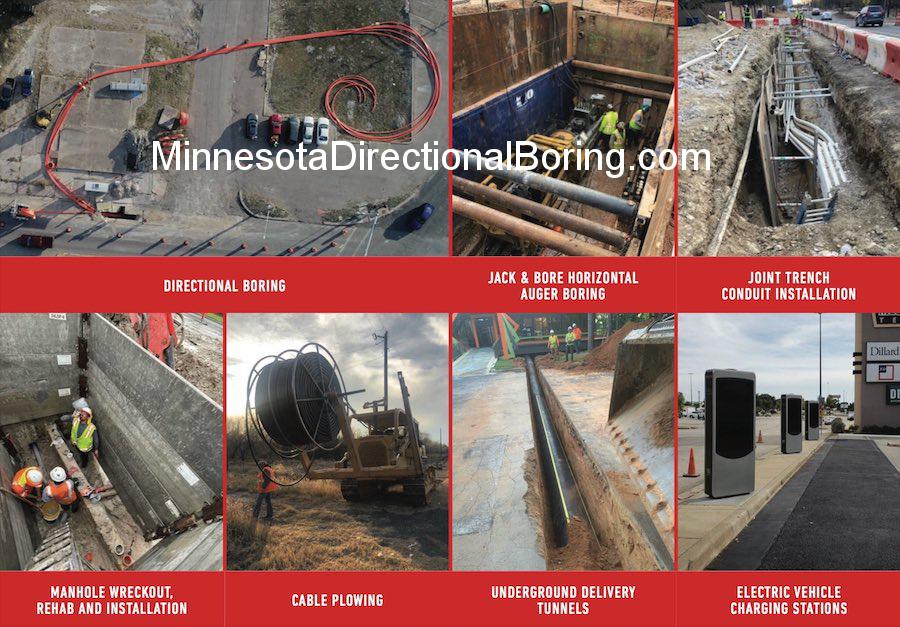

Utility boring is a critical technique in trenchless technology used across a variety of industries, including HDD (Horizontal Directional Drilling), directional boring, horizontal auger boring, jack and bore, and other applications involving the installation of utilities. Here’s how utility boring is utilized in each of these contexts:

Minnesota Directional Boring - Utility Boring Contractors Companies

1. Horizontal Directional Drilling (HDD)

- Application: Installing utilities such as fiber optic cables, water pipelines, sewer lines, oil and gas pipelines, and electrical conduits.

- Process: A pilot bore is drilled along a pre-determined path, followed by reaming to enlarge the hole, and then pulling back the utility pipe.

- Advantages: Ideal for crossing obstacles such as rivers, roads, or densely populated areas without disrupting surface activities.

2. Directional Boring

- Application: Often used for short-to-medium-length utility installations, including electrical cables, irrigation systems, or water pipelines.

- Process: Similar to HDD but typically for smaller-diameter pipes and shallower depths.

- Advantages: Cost-effective and efficient for urban settings or areas with light traffic disruption needs.

3. Trenchless Boring

- Application: A broad term encompassing methods like HDD, jack and bore, and auger boring to install or repair underground utilities.

- Process: Avoids traditional trench digging by creating underground pathways for utility lines.

- Advantages: Minimizes environmental impact, reduces restoration costs, and accelerates project timelines.

4. Horizontal Auger Boring

- Application: Commonly used for installing sewer and water lines beneath roads or railways.

- Process: A rotating cutting head on a casing is pushed through the ground to excavate a path for the utility line.

- Advantages: Suitable for large-diameter pipes and specific soil types, particularly when a precise, straight path is required.

5. Jack and Bore

- Application: Installing casings for utility lines like sewer, water, oil, and gas lines under existing infrastructure.

- Process: A hydraulic jack pushes a steel casing into the ground while an auger removes soil inside the casing.

- Advantages: Extremely precise and effective for short, straight utility installations under obstacles.

6. Electric Utility Installations

- Utility Boring Role: Used to safely and efficiently install underground power cables, reducing exposure to weather-related damage and improving reliability.

- Key Methods: HDD and directional boring ensure minimal disruption to urban areas.

7. Fiber Optic Cables

- Utility Boring Role: Essential for burying fiber networks for internet and telecommunication infrastructure.

- Key Methods: HDD is the preferred method due to its ability to navigate around existing underground utilities and through various soil types.

8. Sewer and Water Lines

- Utility Boring Role: Used to install or replace pipes with minimal disruption to existing infrastructure.

- Key Methods: Horizontal auger boring and jack and bore are common due to their precision and ability to handle larger-diameter pipes.

9. Oil & Gas Pipelines

- Utility Boring Role: Critical for installing long-distance pipelines across challenging terrains like rivers, highways, or mountainous areas.

- Key Methods: HDD is favored for its ability to create long, curved bores suitable for large-diameter pipelines.

10. Irrigation Systems

- Utility Boring Role: Used to install pipelines for transporting water to agricultural fields or golf courses.

- Key Methods: Directional boring provides a cost-effective solution for covering long distances with minimal soil disturbance.

Minnesota Directional Boring - Utility Boring Contractors Near Me

Advantages of Utility Boring Across Applications

- Minimal Surface Disruption: Preserves roads, landscapes, and infrastructure.

- Environmentally Friendly: Reduces ecological impact compared to traditional trenching.

- Cost-Effective: Decreases restoration and labor costs.

- Precision and Versatility: Adapts to different soil types and installation requirements.

- Enhanced Safety: Reduces the risk of damaging existing utilities during installation.

Utility boring techniques like HDD, directional boring, and jack and bore have become indispensable in modern infrastructure projects, ensuring efficient, sustainable, and reliable installation of utilities in diverse environments.